Esta es una pregunta que nos llega con gran frecuencia. La respuesta siempre es la misma, depende de la aplicación.

Repasemos algunas de las aplicaciones más frecuentes del Neón LED:

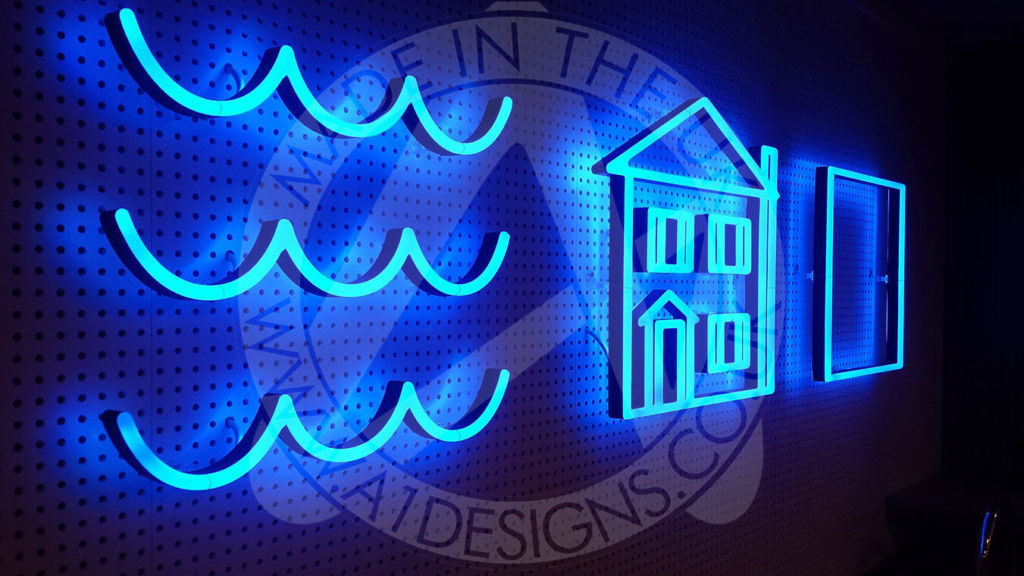

- Iluminación / Decoración de fachadas o interiores: Se utilizan largos tramos, con lineas rectas en su mayoría, que suelen instalarse en altura, no estando al alcance de la mano de cualquier persona. Para estos casos donde no es un requisito el corte a una medida exacta, y donde el neón led no queda al alcance de la mano, recomendamos la versión de 8 x 16 mms (ancho x alto) con una tensión de 220 volt. La principal ventaja de esta versión es que no requiere fuente de alimentación, en su lugar se usa un conector que incorpora un rectificador de tensión y un enchufe que va directo a la tensión de red, 220 volt. Las desventajas son, en primer lugar que las marcas de corte son cada un metro, y en segundo lugar que la tensión de trabajo no es segura, considerando el riesgo del instalador y de una persona que sin conocimientos, manipula el neón led, sacandole la tapa final o el conector, estando este enchufado.

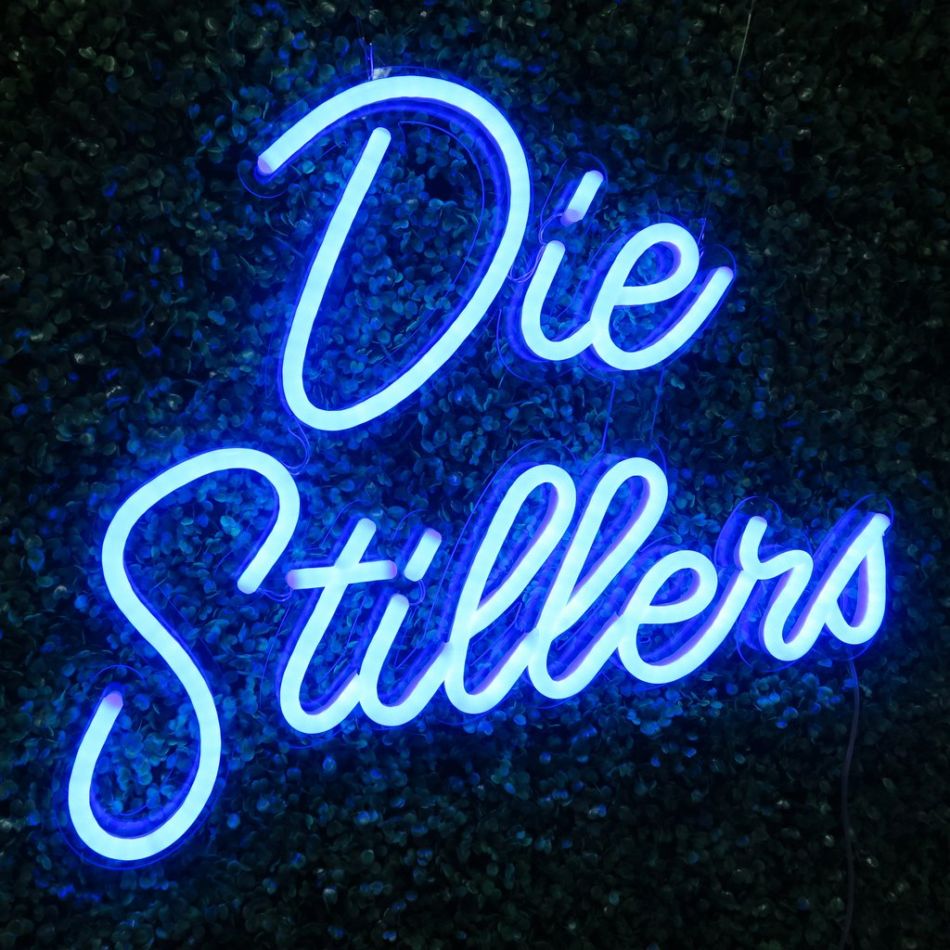

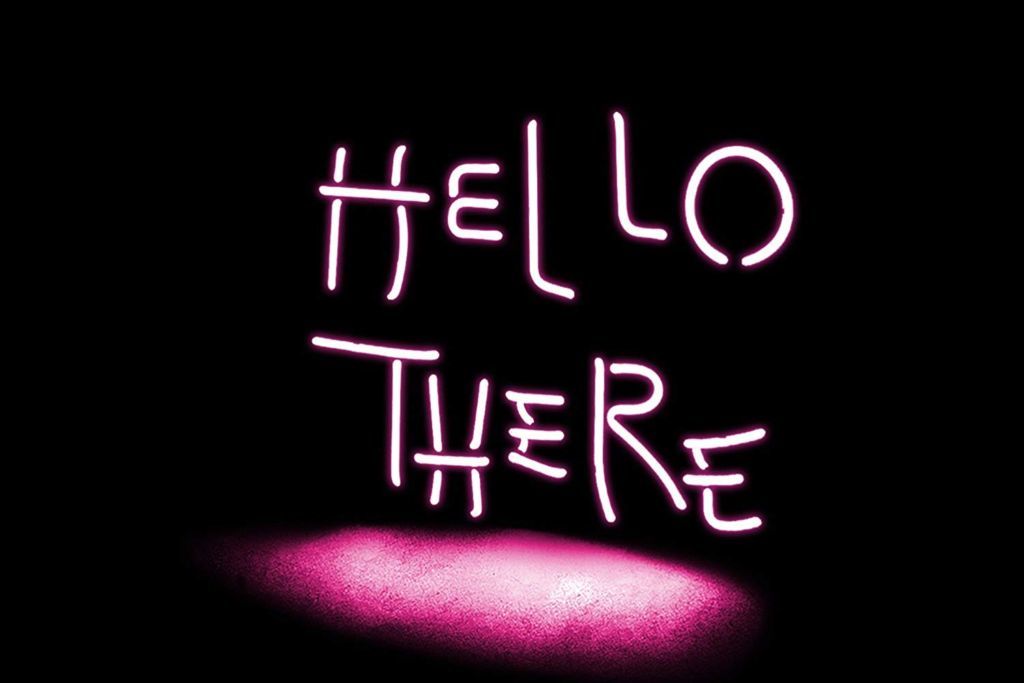

- Cartelería pequeña con figuras y letras con curvas cerradas: Se usan pequeños tramos, con poca presencia de líneas rectas, curvas cerradas, suelen ubicarse en la linea de vista y requieren exactitud en la medida de cada tramo. Para esta aplicación recomendamos la versión de 6 x 10 mms (ancho x alto) de 12 volt, que permite una gran flexibilidad, precisión en el corte (líneas de corte cada 2,5 cms), y la seguridad de poder manipularlo sin estar expuesto a riesgo eléctrico.

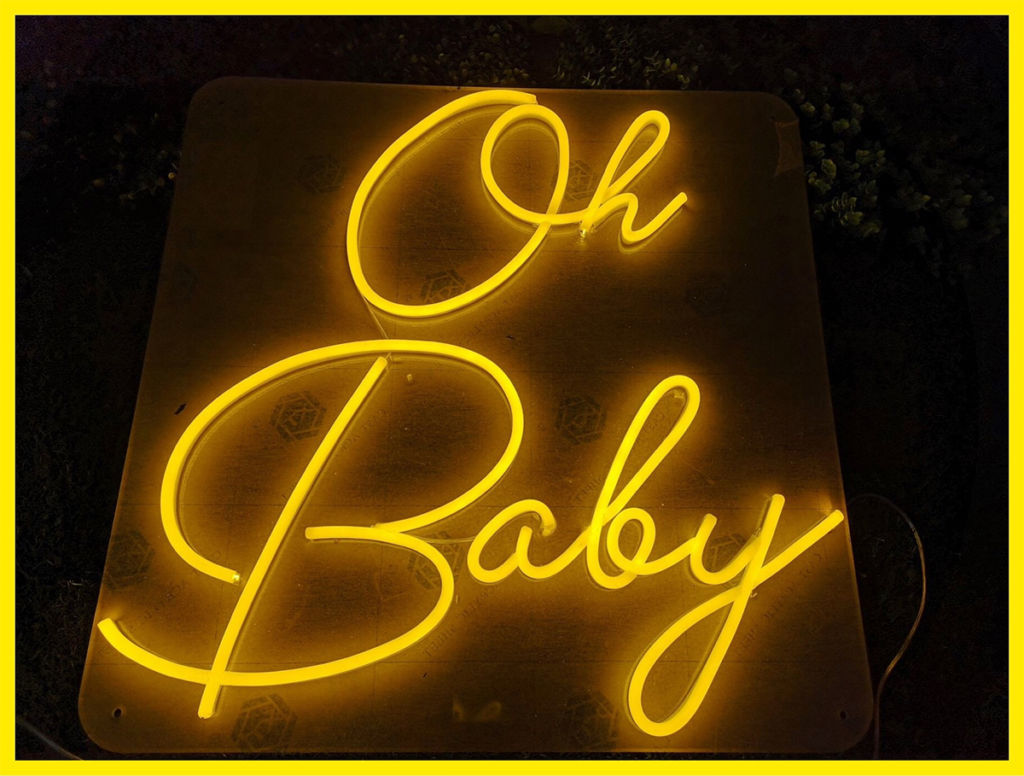

- Cartelería mediana / grande con letras y/o figuras con curvas suaves que pueden estar ubicados a mayor distancia o altura: Si bien se necesita exactitud en la medida de los tramos para formar con precisión las figuras o letras, las curvas no son tan cerradas en comparación con la aplicación anterior. Para estos casos recomendamos la versión de 8 x 16 mms (ancho x alto) de 12 volt, que ofrece una mayor superficie de irradiación de luz, dado que la silicona donde se refracta el haz lumínico es 2 mms más ancha que para la versión de 6 mms. Esta versión ofrece también precisión en el corte (líneas de corte cada 2,5 cms), y la seguridad de poder manipularlo sin estar expuesto a riesgo eléctrico. La desventaja con respecto a la versión de 6 mms es la menor flexibilidad.